The construction industry is known for its complex and time-consuming processes.

However, with the advent of PS wall panel manufacture, there has been a significant shift towards streamlining construction projects.

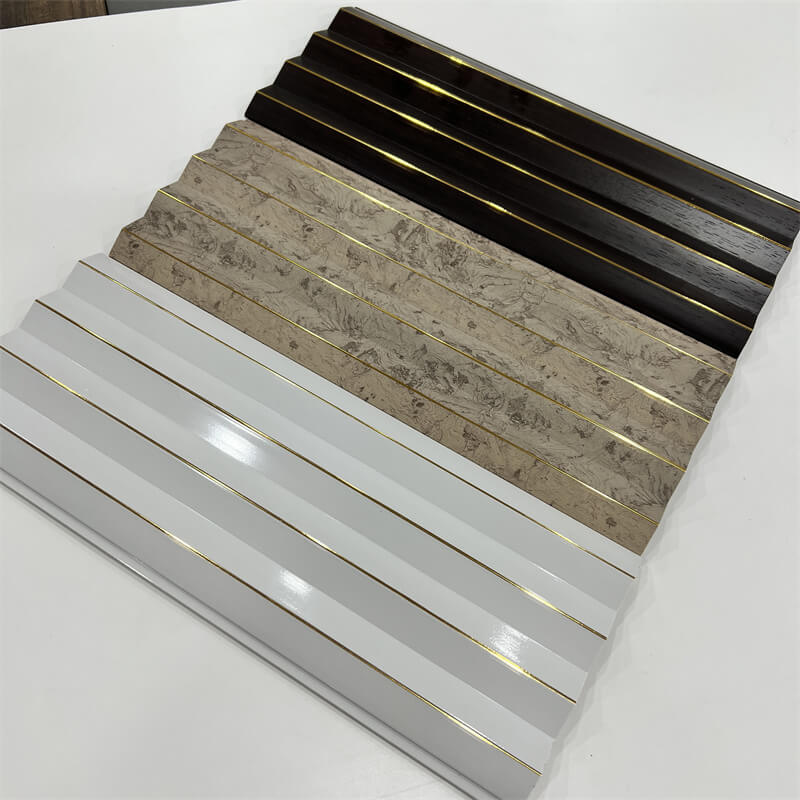

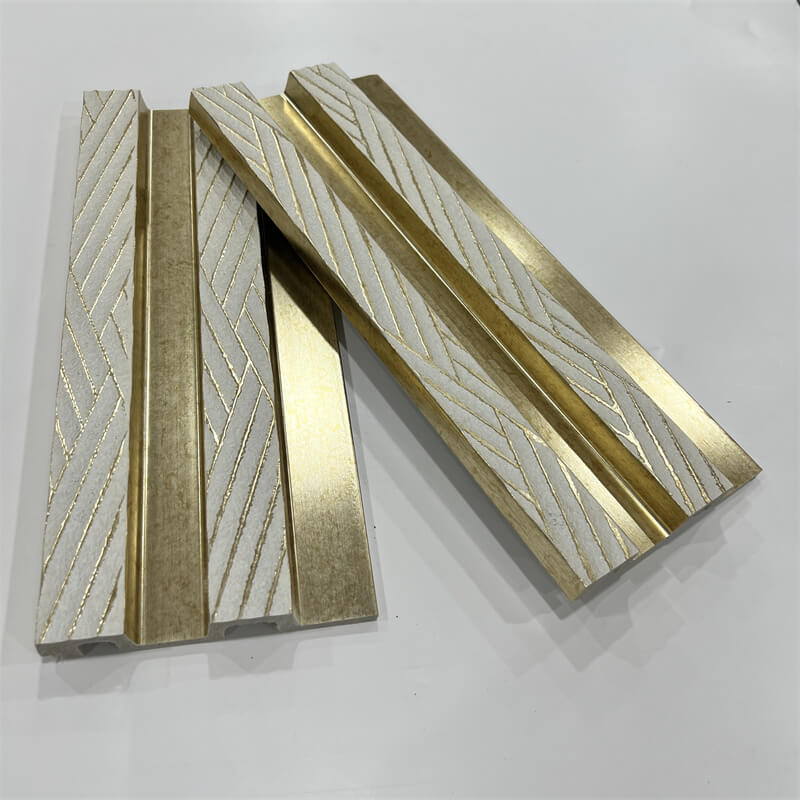

PS wall panels, made from expanded polystyrene, offer numerous advantages that streamline various stages of construction.

From faster installation and reduced labor requirements to enhanced project efficiency and cost savings, PS wall panels are transforming the way buildings are constructed.

In this article, we will explore how PS wall panel manufacture streamlines construction processes and revolutionizes the industry.

Rapid Installation and Time Efficiency

One of the key benefits of PS wall panels is their rapid installation process, significantly reducing construction time.

These lightweight panels are pre-fabricated off-site, allowing for efficient assembly and quick installation on-site.

Compared to traditional construction methods, which require extensive on-site labor and time-consuming processes, PS wall panels can be erected in a fraction of the time.

This time efficiency not only accelerates project timelines but also minimizes disruption to neighboring structures and reduces associated costs.

Reduction in Labor Requirements

PS wall panel manufacture also streamlines construction processes by reducing labor requirements.

The pre-fabricated nature of PS wall panels eliminates the need for extensive on-site construction work, such as mixing concrete, forming molds, and pouring foundations.

With panels ready to be installed, fewer workers are needed for construction, resulting in reduced labor costs.

This efficiency allows construction teams to focus on other critical tasks, such as site preparation, interior finishing, and overall project coordination.

Improved Project Efficiency and Coordination

PS wall panels contribute to improved project efficiency and coordination.

The off-site fabrication of these panels allows for better project planning and coordination, as construction teams can work in parallel with other trades.

The predictability and precision of PS wall panels also reduce errors and rework, minimizing delays and ensuring smoother project progress.

Additionally, the modular nature of these panels enables better project sequencing, allowing for concurrent work on different parts of the building.

This streamlined coordination enhances overall project efficiency and contributes to timely project completion.

Cost Savings and Resource Optimization

PS wall panel manufacture offers significant cost savings and resource optimization.

The reduced labor requirements and accelerated construction timelines result in lower labor costs.

Moreover, the lightweight nature of PS wall panels translates into savings in transportation and logistics, as smaller vehicles can be used for delivery.

Additionally, the energy-efficient properties of PS wall panels contribute to long-term cost savings for building owners through reduced energy consumption.

Furthermore, the optimization of materials and reduction in waste generation during panel fabrication also contribute to cost savings and environmental sustainability.

PS wall panel manufacture has emerged as a game-changer in the construction industry by streamlining construction processes.

The rapid installation, reduced labor requirements, improved project efficiency, and cost savings associated with PS wall panels are transforming the way buildings are constructed.

As the industry increasingly embraces the benefits of PS wall panels, we can expect to see greater adoption and advancements in manufacturing techniques, further streamlining construction processes.

With their ability to expedite timelines, optimize resources, and enhance project coordination, PS wall panels are paving the way for more efficient and cost-effective construction practices.

The future of construction lies in the seamless integration of PS wall panel manufacture, unlocking new levels of productivity and success in the industry.